Surface defect detection at local nodes: combining YOLO with PyQ

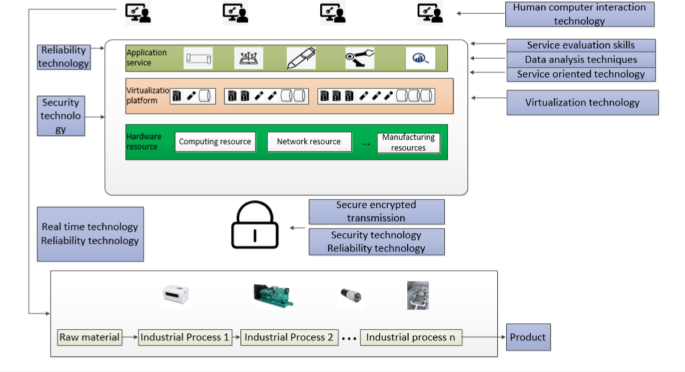

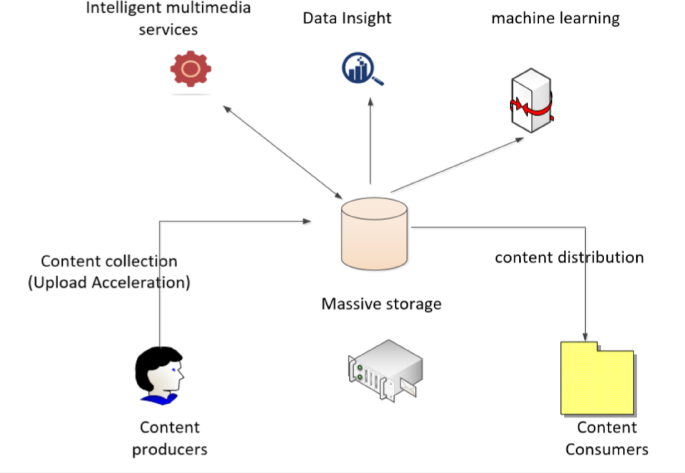

This paper integrates the YOLO object detection algorithm with the PyQt framework. A model with satisfactory performance after training is utilized, and the system framework is depicted in Fig. 3. The user interface is designed and implemented under the PyQt framework, integrating the YOLO model into the GUI. A video stream/image processing module is created in this study, initiating video stream/image processing and implementing user interaction functionalities, including responding to user operations20,21,22,23. This method effectively achieves efficient and accurate steel surface defect detection by combining the YOLO object detection algorithm with the PyQt framework. It offers significant advantages such as real-time capability, accuracy, user-friendliness, integrability, automation, and adaptability.

The seamless integration of PyQt framework with YOLO in this research achieves an efficient information transmission mechanism. This mechanism processes user interaction events through a signal-slot design pattern, transferring captured image data to the YOLO model via multi-threading while avoiding UI thread blocking. The system employs asynchronous processing methods and local caching strategies, ensuring stability under various network conditions. Through data serialization in JSON format, combined with REST API design, efficient communication between local nodes and cloud services is realized. Detection results are intuitively presented through the interface while being serialized and transmitted to cloud services for further distribution, providing reliable assurance for real-time applications.

cloud data push: utilizing Qiniu cloud service

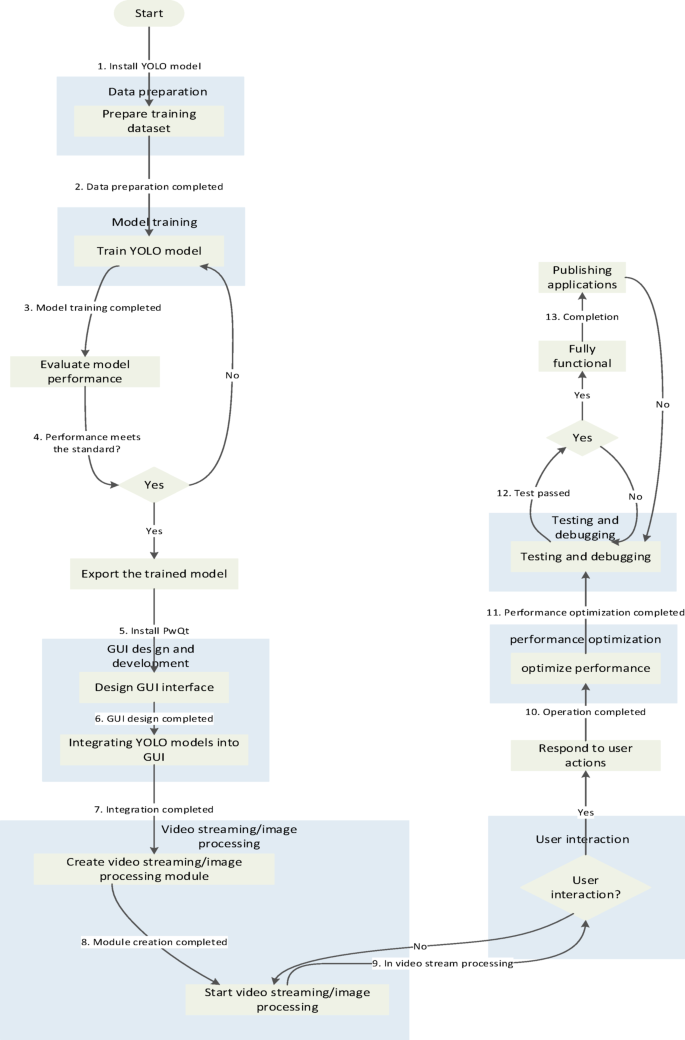

This paper adopts Qiniu Cloud technology to realize cloud data storage, transfer, and push. Qiniu Cloud enables functionalities including object storage, file storage, and CDN acceleration, offering innovative and flexible combinations for industrial scenarios based on massive data. The specific architecture of cloud data processing based on Qiniu Cloud is illustrated in Fig. 4.

This paper utilizes Qiniu Cloud’s object storage service to store a large amount of deep learning-detected steel surface defect results, ensuring the security and reliability of the data. Upon receiving data, CDN acceleration service is employed to achieve high-speed data push and distribution, enabling rapid transmission and access of data globally, thereby providing users with a fast and stable data access experience.

Steel surface defect multi-mode full-process detection based on meow reminder

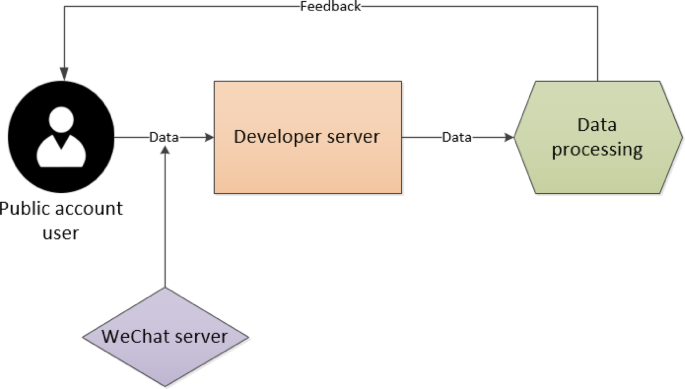

Meow Reminder is a WeChat public account that provides intelligent reminder services, assisting users in receiving real-time information through its push function. The integrated steel surface defect multi-mode full-process detection system, incorporating human-computer interaction technology and deep learning algorithms, can promptly identify and classify defects during the production process by monitoring and analyzing images of the steel surface in real time. The WeChat server data processing flowchart is depicted in Fig. 5. Leveraging Meow Reminder’s push function and cloud technology, this system achieves real-time transmission of defect information, significantly enhancing the accuracy and efficiency of steel surface quality control. The system’s design takes into account its flexible adaptability, enabling continuous optimization with advancements in production technology and changes in market demand, further reducing scrap rates and saving production costs.

-

(1)

WeChat and Email Push.

This paper integrates the transformed cloud data into a WeChat public account to provide data to it. The public account can promptly send this data to the developer’s server database for storage and further processing. The processed results are quickly returned to the users, enabling them to promptly obtain the desired information. WeChat public accounts also support various data formats and interaction methods, providing users with convenient and efficient data services. The WeChat server data processing flowchart is illustrated in Fig. 5. This paper realizes the efficient sharing and utilization of cloud data on the WeChat platform and via email, offering researchers a more convenient means for data processing and analysis.

-

(2)

iMessage push on apple devices.

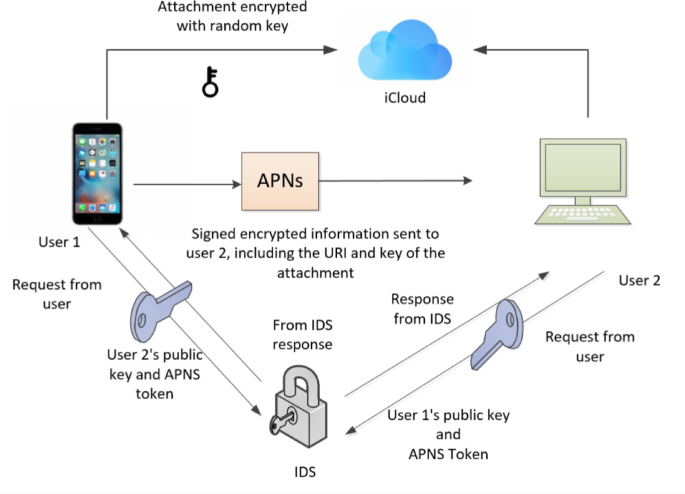

After rigorously detecting and processing information using deep learning algorithms, this paper sends secure and compliant information to users through the iMessage instant messaging platform. The conventional encryption of iMessage ensures the confidentiality and integrity of the above content, as shown in Fig. 6. This process covers key steps such as filtering, identification, and encryption of message content, ensuring the security, integrity, and timeliness of information during transmission. Through this mechanism, the paper achieves effective management and control of user-received information, enhancing the reliability of information dissemination and user experience.

-

(3)

Push notifications for android users.

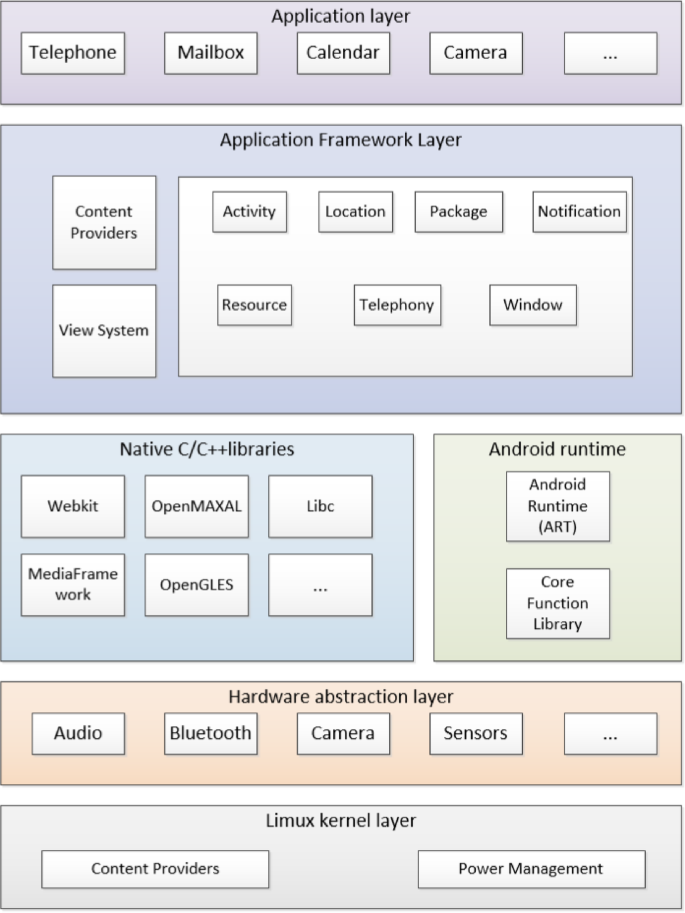

The Android system is an open-source smart terminal operating system developed by Google in the United States and is favored by numerous developers and users worldwide. Its system architecture, as depicted in Fig. 7, comprises five levels, including the application layer, application framework layer, system runtime library layer, hardware abstraction layer, and Linux kernel layer, each fulfilling different functions and roles. Due to the open-source nature and customization features of the Android system, it faces challenges in terms of version compatibility and system stability, requiring developers to conduct meticulous adaptation and optimization work. This paper implements the push function of detection results using deep learning algorithms on the Android operating system, providing users with real-time detection result push services by integrating detection results into Android applications. This implementation not only enhances user experience but also ensures the timeliness and accuracy of detection results.

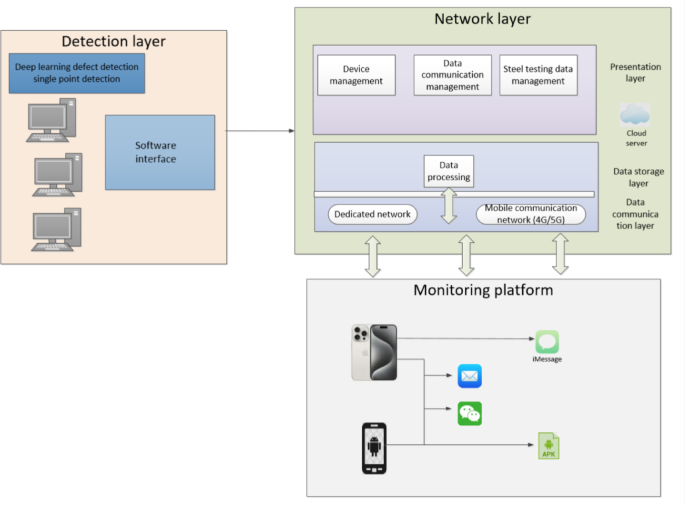

This study focuses on the design of a multi-modal intelligent detection system architecture for surface defects in steel based on cloud computing technology. The system utilizes deep learning algorithms and integrates artificial intelligence with cloud computing resources to ensure efficient flow and rapid processing of real-time data. The system’s powerful push function can promptly and effectively send detection results to users, with the specific system architecture depicted in Fig. 8. Regardless of whether users are using the Android or iOS operating system, the system can distribute detection reports to users through various channels, including WeChat and email. For iOS users, the system can also send notifications using iMessage, while for Android users, real-time notifications can be received through the application.

This research demonstrates an innovative integration application of existing commercial interfaces through Meow Reminder’s WeChat push functionality, with its primary scientific and engineering contributions including: (1) The design of a multi-channel push framework for defect detection results suitable for industrial environments, effectively reducing information transmission delays; (2) The implementation of a unified cross-platform push mechanism, addressing the challenge of information synchronization between different devices; (3) The extension of standardized interface patterns, enhancing compatibility with existing industrial systems. Compared to existing methods, this system shows significant improvements in push efficiency and exhibits excellent stability under various industrial environmental conditions.